Fiberglass Boss Pipe United States

We are partnered with Boss Pipe: an experienced team of centrifugally cast fiberglass reinforced polymer mortar pipes (CCFRPM) providers featuring some of the world’s biggest and best manufacturers in the business.

The DFHB factory has been producing our BossPipe brand of centrifugally cast fiberglass reinforced polymer mortar (CCFRPM) Jacking Pipe for years and has proven to be a very successful ISI supply partner. They are without question one of the best CCFRPM pipes manufacturers in the industry.

DFHB has become a world leader in the supply of FRP pipe and Jacking Pipe in particular. They have been successfully supplying pipe and supporting projects throughout the globe for over 20 years. DFHB has championed the method of centrifugally cast fiberglass reinforced polymer mortar pipes (CCFRPM). Their factory is one of the (if not the) busiest in the world. In most recent years, they have led the way in innovation and development of their Centrifugally Casting technology.

DOWNLOAD

BossPipe Brochure

CCFRPM Jacking Pipe

What is Centrifugally Cast Fiberglass Reinforced Polymer Mortar Pipe?

CCFRPM is a unique type of pipe that is strong and lightweight with consistent dimensions, a smooth surface and the ideal level of stiffness. These pipes are a smart choice for certain kinds of construction projects, as they are made from corrosion resistant materials. CCFRPM pipes can have a service life of up to 100 years and possibly more.

• High strength

• HIgh Stiffness

• Corrosion Resistant

Jacking Pipes

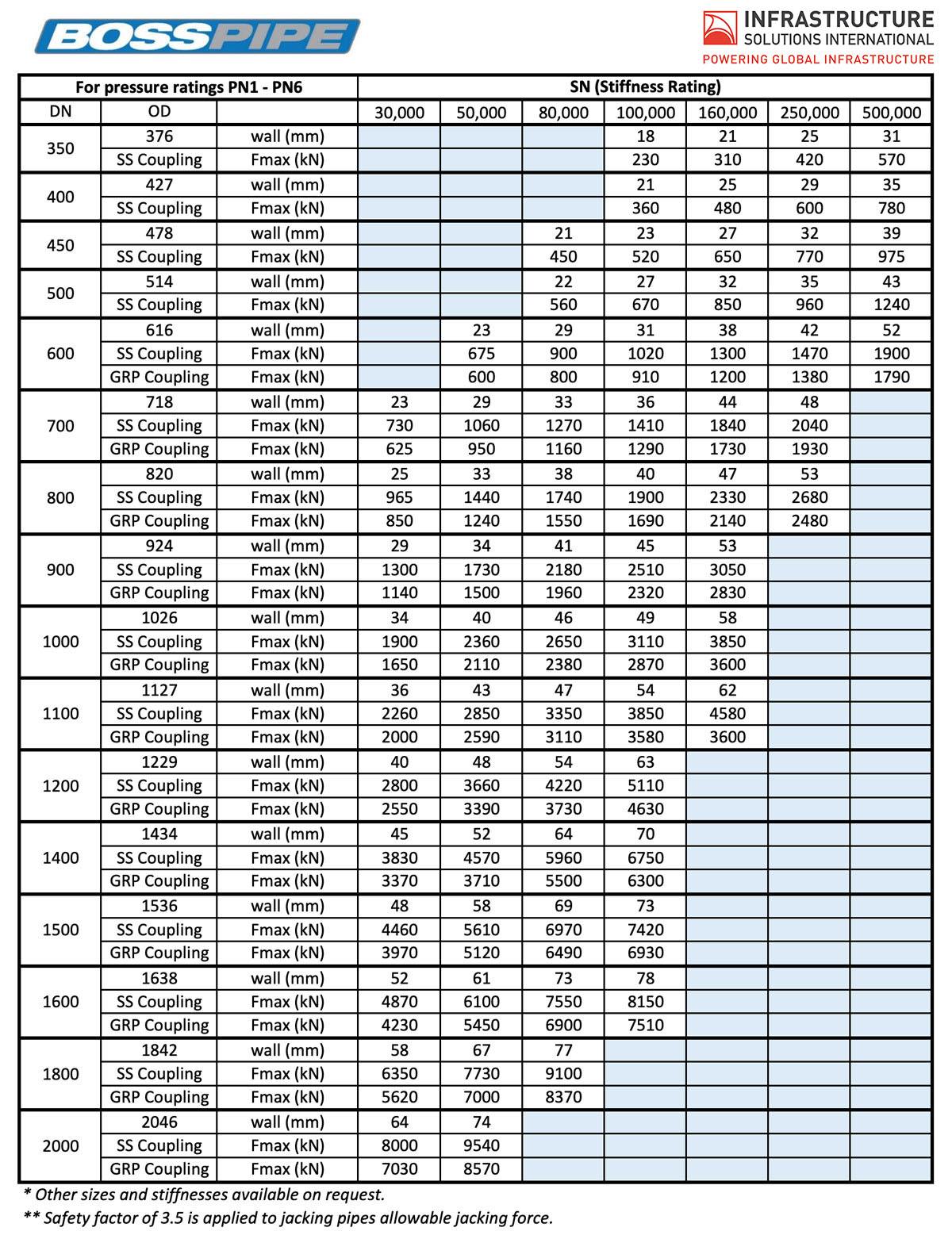

Fiberglass Reinforced Polyester (FRP) jacking pipes are typically utilised in the trenchless construction of water and wastewater pipelines. This type of jacking pipe is produced in a standard length of 1, 2, 3 and 6m (company standards). Of course other bespoke pipe lengths can also be supplied on request, simply ask us to arrange this for you.

Applications

Boss Pipe offer a product with several beneficial qualities including a brilliant combination of high strength and flexibility. As the materials used offer corrosion resistance, systems built using FRP pipes are ideal for use in numerous applications, including water supply, sewerage, drainage, transport of slurries, and industrial processing plants.

Worldwide uses for CC-FRPM jacking pipes:

- Gravity Sewers

- Pressure / force main sewers

- Potable water lines

- Relining

- Hydro-electric plants

- Industrial pipelines

- Double pipelines

- Water and sewer treatment plants

- Pipe jacking

- Bore casting, ventilation shafts and ducts

- Submarine pipes and outfalls (where GRP pipes used)

- Special applications i.e. manholes

Benefits of Boss Pipe FRP pipe systems:

- A-grade chemical and corrosion resistance

- Ability to resist high static and axial loads

- High hydraulic efficiency

- High abrasive resistance

- High durability – 100-year design life!

- Resistant to UV light and frost

- Constant outside diameter for CC pipe

- Constant inside diameter for wound pipe

- Choice of fittings

- Push-fit sleeve coupling (couplings accommodate angular deflection).

Ask us if this specialist product is the best choice for your project – and if so we’ll discuss options with you to get things moving.